The functionality of machinery and mechanical systems is dependent on each component. The idler gear is a crucial component that cannot be overlooked.

This article aims to shed light on the purpose of an idler gear, its importance in various applications, and how it optimizes mechanical efficiency.

What is an Idler Gear?

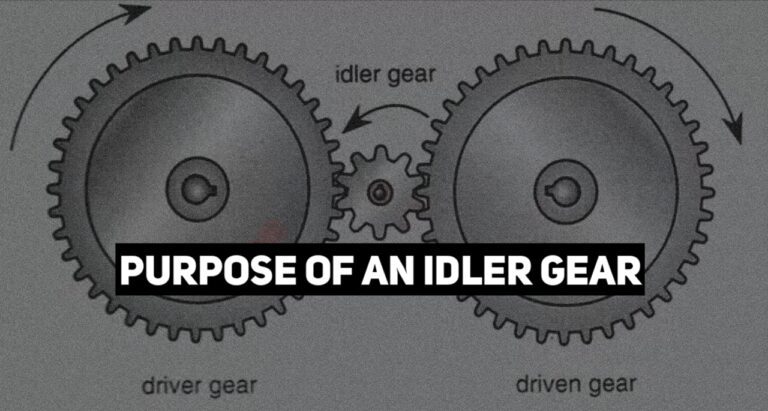

An idler gear, also known as a dummy gear or intermediate gear, is a gear that is positioned between two other gears, primarily serving as a connector or a spacer.

Unlike the driving and driven gears, the idler gear doesn’t alter the speed or direction of rotation. Instead, it helps transmit power between the driving and driven gears while maintaining a constant speed ratio.

You can check out this page about idler-wheel on Wikipedia.

Functions of an Idler Gear

Directional Change:

The primary purpose of an idler gear is to change the direction of rotation in a gear system. By meshing with both the driving and driven gears, the idler gear ensures that the rotation is transmitted smoothly, redirecting the power flow at a different angle.

This directional change is crucial in various mechanical applications, such as automobiles, industrial machinery, and clockwork mechanisms.

Power Transmission and Load Distribution:

Idler gears play a significant role in distributing power and reducing excessive wear on gears within a system. By acting as an intermediary, the idler gear distributes the torque evenly across the driving and driven gears, preventing excessive strain on a single-gear tooth.

This load distribution helps enhance the overall durability and longevity of the gear system.

Tension and Timing Adjustment:

In specific systems, such as automotive engines, an idler gear is utilized to maintain proper belt tension and adjust timing.

Introducing an idler gear along the belt path can help ensure the optimal tension of the belt, preventing slippage or misalignment.

Additionally, in timing belt-driven systems, the idler gear assists in synchronizing the rotation of multiple components, enhancing precision and efficiency.

Noise and Vibration Reduction:

Idler gears can also serve as vibration dampeners within a gear system. By introducing an additional gear into the meshing mechanism, the idler gear helps absorb or distribute vibrations, reducing noise and ensuring smoother operation.

This is particularly crucial in precision machinery, where minimizing vibration and noise is essential for accuracy and user comfort.

For further clarification, check out this idler gear discussion on Quora.

Applications of Idler Gears

Idler gears find extensive usage across various industries and mechanical systems, including:

Automotive Industry:

In automobiles, idler gears are commonly found in timing belts or chain systems, ensuring proper synchronization of engine components, such as camshafts and crankshafts. They also help maintain the tension of accessory drive belts, such as serpentine belts.

Industrial Machinery:

Idler gears play a crucial role in the world of industrial machinery. They are essential components in conveyor systems, printing machines, and manufacturing equipment. Their primary function is to ensure the smooth transfer of power and direction changes, which significantly enhances the efficiency of the machinery.

Clockwork Mechanisms:

In traditional clockwork mechanisms, idler gears play a crucial role in regulating the movement of hands and ensuring accurate timekeeping. These gears help transmit power from the main drive gear to different secondary gears, resulting in precise and reliable timekeeping.

FAQs

What is an idler gear used for in a five-speed manual transmission?

In a five-speed manual transmission, the idler gear serves multiple essential functions. It facilitates gear synchronization during shifting, ensuring smooth transitions between gears. The idler gear is responsible for engaging the reverse gear, allowing the vehicle to move in the opposite direction. It also helps maintain proper spacing and alignment between gears, distributing the load evenly and reducing wear and tear. Additionally, the idler gear contributes to noise and vibration reduction within the transmission system.

Do idler gears affect torque?

No, idler gears don’t affect the torque and speed of the engine.

How are idler gears used in transmissions to drive a vehicle?

Idler gears are used in vehicle transmissions to facilitate gear shifting and power transmission. They synchronize the rotational speeds of the driving and driven gears, allowing for smooth engagement and proper gear selection.

Idler gears act as intermediaries, transmitting power from the engine to the wheels through meshing with the driven gear.

They also play a role in changing the direction of rotation, such as in reverse gear. Additionally, idler gears assist in smooth gear shifting by providing a neutral position.

As an Amazon Service LLC Program Associate, V. Auto Basics earns from qualifying purchases. See Our Affiliate disclaimer.